Can a CNC milling machine make precision parts for different products?

A CNC Milling machine uses a computer numerical control system of automation to create specific parts of products for several industries such as manufacturing and medical. CNC milling machines can work on various materials such as brass, steel, copper, wood, fiberglass, titanium, foam, ABS, nylon, polypropylene, and more. However, some materials can be too soft or too hard for CNC machinings like rubber or silicone which are too soft for machining, or materials like ceramic which can be too hard for making precision parts.

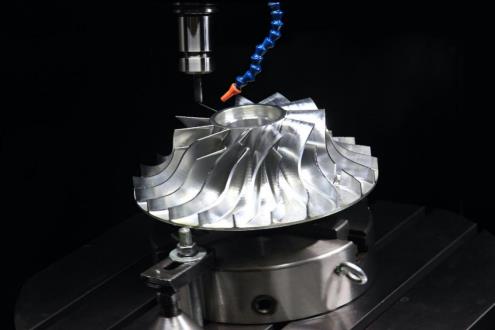

Milling is the process of using a rotating multi-edged tool to effectively and efficiently cut and alter workpieces to get desired results. Milling is suitable for processing various forming surfaces like splines, threads, and gears as well as planes and grooves and specifically shaped molds. The movement of the milling machine depends on the machine used. The main movement, feed direction and speed are up and down millings.

A CNC Milling machine can make precision parts for different products but this varies with the complexity of the parts being designed. The designs can go from simple parts to highly complex and demanding parts with curved geometrics. There are different types of CNC Milling machines that can be used depending on the need for precision. Some of them are a CNC lathe, a three-axis CNC milling machine, and a four and five-axis CNC milling machine.

Several factors determine the precision of parts made by a CNC milling machine such as the complexity of the part, the dimensions or geometry, the tolerance, the product it will be used in, and most importantly the type of material.

Distinctive CNC milling machines shift in their sizes, hub arrangements, nourish rates, cutting speed, processing nourishes course and other characteristics. However, in common, CNC plants all utilize a turning shaft to cut absent undesirable fabric. They are utilized to cut difficult metals such as steel and titanium but can moreover be utilized with materials such as plastic and aluminum. CNC plants are built for repeatability and can be utilized for everything from prototyping to tall volume generation. High-end exactness CNC plants are regularly utilized for tight resilience work such as processing fine passes on and molds.

While CNC processing can provide a fast turnaround, as-milled wrapping up makes parts with unmistakable apparatus marks. It may deliver parts with a few sharp edges and burrs, so extra forms may be required on the off chance that edges and burrs are unsatisfactory for those features. Of course, deburring instruments modified into the grouping will deburr, even though as a rule accomplishing 90% of the finished prerequisite at most.

Generally, a complex part will demand more attention and consideration during the machining process, compared to a simple part. This is due to the design, requirements, and specific dimensions. Sometimes whenever possible design engineers should try to simplify some designs so they can be attainable during the milling process. the simpler the design is the easier it will be to create and manufacture hence, reducing the cost of overhead in manufacturing. Creating simple designs requires using fewer materials and components in the process and ensuring optimum performance.

Factors that determine the precision of parts for products.

The Size of the part

The size of a workpiece Is a major factor contributing to the precision of products. Although it's not a major factor alone it is still taken into consideration when preparing to process. however, it is important to remember that larger parts are usually much easier to manufacture compared to smaller and more intricate ones. Some workpieces may require the use of a two-axis CNC milling machine and some may use a five-axis CNC milling machine to reduce the cutting time and have a more polished and accurate piece.

Part processing

This is determined by the number of times engineers will need to intervene during the process and the number of operations the workpiece will have to go through to get the desired results. This mostly depends on the workpiece's geometry, tolerance, and finishing. A more complex workpiece will have a much longer process and multiple interventions to ensure every detail is in place. This becomes time-consuming and more costly due to several reorientations.

The most appropriate machine to use is a five-axis CNC milling machine because it will require fewer overhead costs and fewer manual interventions.

The part tolerance

The tolerance of the workpiece can also factor into the CNC milling machine used as well as lead time and cost. This can also be determined by the material of the workpiece. This will in turn determine the speed and tools that will be used during the milling process. high tolerance allows for more accurate and precise parts but they are also more costly because of the additional input of tools and machines and interventions that the workpiece requires.

Part Finishing

The finishing of a workpiece is also a factor in precision and whether a CNC machine can accurately create precise workpieces for different products.

Bead Blasting

Bead blasting includes the expulsion of any surface stores or blemishes on a portion for a more uniform, smooth wrap-up. The sphere-shaped beads guarantee a steady wrap-up and are commonly utilized to offer a matt wrap-up. Better beads can too be utilized for a more satin-like or gloomy finish.

Anodized finishes

Anodized finishes offer an indicated wear-resistant coating, ordinarily accessible in several colors. Anodizing is for the most part straightforward, and the layer is more often than not lean so be beyond any doubt to consider the CNC Machine marks on the surface.

As machined

Another wrap-up will take off the surface harshness as the piece is machined. The precise benefit unpleasantness is decided to utilize the Ra esteem. Regularly the surface harshness for CNC machined parts is Ra 3.2µm.

CNC machining is one of the foremost prevalent manufacturing processes today. And this can be basically due to its tall accuracy, precision, and tight resistance extend. In reality, with CNC machining, you'll be able precisely to make over 1000 units of indistinguishable parts while accomplishing resilience as little as ±0.04 mm.