Item NO.:

SUS001Payment:

TT ,For products Prepaid 30%, 70% before shipProduct Origin:

ChinaColor:

NaturalOrder(MOQ):

10Shipping Port:

XiamenLead Time:

30 days

The working principle of CNC lathe

CNC Turning is rotating tool to cut the workpiece, cnc turning parts is rotated rather than the tool. turning parts manufacturing is the most basic and common cutting. cnc turning services is suitable for machining rotating surfaces. Most precision turning parts with rotating surfaces can be done by turning methods, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, threads, and rotating forming surfaces. The tools used are mainly turning tools.The material can be aluminum, brass, stainless steel and steel.

Do you know the advantages and disadvantages of different lathe

Choosing the right machine according to different materials and structures is the key to reducing costs and improving accuracy and quality

|

Lathe type |

Advantages and disadvantages |

Suitable material |

Some applicable industries |

|

Automatic lathe |

only manufacturing turning parts within the outer diameter Φ20MM or less, One person can operate multiple machines, the lowest cost machine in cnc turning services. |

Aluminum,Copper, Iron, SUS303,POM |

Copper nuts, rivets,Connector parts |

|

CNC lathe |

Split cutter lathe and turret lathe, Split cutter lathe is suitable for parts with an outer diameter of Φ45MM or less, a length of less than 100MM, and simpler parts. It is characterized by high efficiency. The turret lathe is suitable for thin and long parts. |

Aluminum, copper, stainless steel, iron, titanium alloy, POM |

Flashlight housing, shaft, electronic cigarette parts |

|

Turn-mill combination |

The precision turning parts can be processed at one time, and the geometric tolerance is high, but because the fourth axis speed is low, the turning time is slow. |

Aluminum, copper, stainless steel, iron, titanium alloy, POM |

Precision connector parts |

|

Citizen swiss Automatic Lathe |

Turn slender parts and the fourth axis can be processed at one time. |

Aluminum, copper, stainless steel, POM |

Printer shaft,Connector parts |

CNC lathe machining electronic stainless steel parts

There are 18 sets cnc lathe machine,the tolerance can meet 0.01~0.02mm,the max dimension can reach 500mm,cnc lathe machine is suitable for processing less quantitty high precison spare parts.we have professional engineers and inspection team. Short lead time and fast delivery make us win good reviews from worldwide clients.we will offer you professional assistance and products based on the requirements. If your parts need to be machined with tight tolerance, please tell us the details. Precise dimensions and smooth surface can be achieved.Stainless steel products can be processed with our CNC turning services, milling services, and drilling services, as well as threading, grinding, knurling, or other techniques. We can also provide one-stop shopping OEM. EXPRESS, BY SEA OR BY AIR on your request, well packed and fast delivery to ensure you get the complete product as soon as possible.

CNC lathe machining stainless steel Parts Advantages:

– Can processs large dimension less quantity products

– Specialized in CNC manufacturing and design more than 18 years

– A variety of machining operations are available

– Can meet high precision requirements

|

Matrial |

Stainless steel |

| Surface treatment | Natural |

| Processing | Cnc lathe machining |

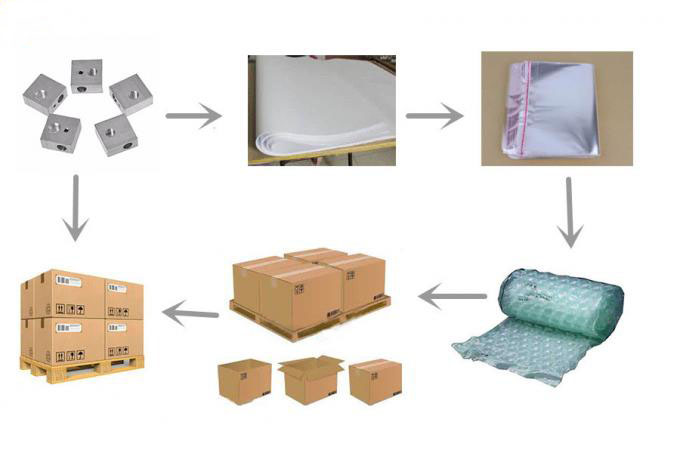

| Packing |

Inner with the plastic bag and PE Foam, outer with carton. We can pack as per customer’s requirement. |

|

Application |

Electronic industry |

| Tolearance | Can keep +/-0.02mm, high accuracy |

| Specification: |

Products can be produced as per customer’s drawings. |

|

Drawing Software: |

CAD/Solidworks/CAXA/UGNX.10 |

|

Manufacturing Service: |

OEM or ODM is available. |

Process control

| Q C: | Incoming material will be checked carefully before production. |

| Strict processing quality control. | |

| 100% inspection before shipment. |

Quality Assurance & Customer Satisfaction

Located in Xiamen, Fujian, China (Mainland), PRIME manufactures custom parts for clients ranging from government agencies and Fortune 100 companies to inventors, engineers, hobbyists, and students.

To consistently exceed customer expectations, quality control and assurance is achieved through

Detailed records of incoming raw materials

Detailed computer generated traveler tickets

Analysis of root cause of non-conformances

Fully equipped inspection department

Multi-level incoming order review

Fully equipped inspection department

Periodic calibration and labeling of inspection tools

Comprehensive written procedures and policies

Designated areas for nonconforming parts

Corrective actions to prevent recurrence of non-conformances

Daily backup of electronic records stored in multiple locations

Extensive electronic records of orders, customer communications, and inspection results

Comprehensive software expert system advising customers of manufacturability issues

Staff members being strongly encouraged to suggest improvements in methods, materials, and suppliers

F A Q

1. How soon can I get the quotation?

A. We will provide ASAP, within 24 hours after receiving your detailed drawing.

2. What is the MOQ?

A. Usually, we don’t set MOQ, but the more, the cheaper. Besides, we are happy to make prototype or sample for clients to ensure quality standard.

3. DO you provide samples? Is it free or extra?

A. It is an honor to provide a sample. Usually, sample fee is two times of batch unit price and it will be returned to mass production.

4. How long is the Delivery for Your Industrial Part?

A. Honestly, it depends on the order quantity. Normally, 7 days to 20 days after your deposit. We will try our best to shorten our lead time according to customer’s demands.

5. How can you guarantee the quality?

A. Quality is our culture. Quality control department set up control plan before starting the project, and all PPAP report will be provided to the whole process.

Leave A Message

Leave A Message