CNC is an abbreviation that stands for Computer Numerical Control. A CNC milling machine is a type of CNC machining that cuts away a workpiece into the desired shape.

The milling machining involves a cutting tool rotating at a very high speed while removing excess materials from a workpiece that is fixed. This cutting tool is usually attached to a spindle.

CNC milling is the most used CNC process since it is more accurate, and consistent and can increase production and uniformity. CNC milling is a process controlled by a computer. Let us now have a look at how the CNC milling machine is used in medical equipment.

1. Surgical instruments

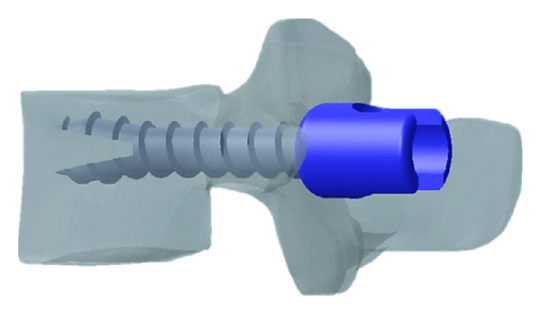

As CNC machining is used to produce surgical instruments milling is done to make them high quality and put them in their required shape. An example of surgical implants made with this machine is bone screws.

Bone screws require flawless finishes to do away with patient discomfort and failure. The CNC milling is done to give them flawlessness and to cut them into the necessary shapes.

CNC milling machines are also used in cutting and shaping other medical devices and instruments used by surgeons during operations such as:

●Blade handles

Blade handles are also known as scalpel handles. They are used by surgeons to hold disposable blades to make incisions during oral surgery. They have different sizes and shapes. The CNC milling machines are used to cut and shape them into these different desired sizes and shapes

●Biopsy tubes

A biopsy tube is a thin lighted hollow and flexible tube used by doctors to remove a piece of tissue or cell samples from the body. Most of this equipment is created using CNC machines.

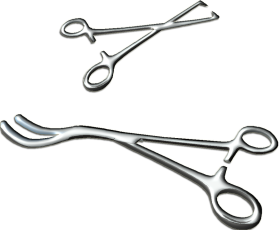

●Forceps

Forceps are surgical instruments used by doctors during surgical operations. There is another type of forceps known as the obstetrical forceps that is used during childbirth to grasp the head of the baby out of the cervix. They both demand a high degree of precision.

They are milled by CNC machines to give them extra flawlessness and desired shapes.

●Implant holders

These are the instruments used by a surgeon to hold the implants in place while implanting or replacing body parts in patients. There are various types of implant holders depending on the type of implant being done. For example, dental implant holders for dental implants.

Their differences come in size, shape, and functionality. Whichever the implant holder, CNC milling machines ensures that they are cut into the required sizes according to their purposes.

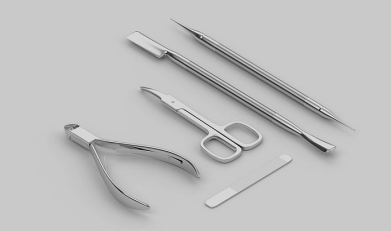

●Surgical scissors

●Clamps

●Cutters

Surgical devices require conscientiousness and are also subject to safety requirements like easy sterilization, CNC milling is the best way to manufacture them due to its accuracy. Also, they ensure comprehensive surface finishing treatments to eliminate surface defects.

2. Manufacturing of extremely small medical parts

Extremely small medical tools such as miniature screws for implants and devices, ophthalmic devices, catheters, drug delivery systems, pacemaker components, and stents, have immense sophistication rolled up in their small sizes that require high expertise.

CNC milling is the ideal choice since it provides high precision levels even for micro components.

3. Medical implants

These are medical parts used by surgeons to replace body parts. Examples are; knee implants and hip replacements. CNC machines are used in the production of these parts. The implants are made from various metals like titanium.

Since CNC machining is compatible with a wide variety of materials, it makes it easier and perfect for these kinds of production processes.

4. Electronic medical equipment

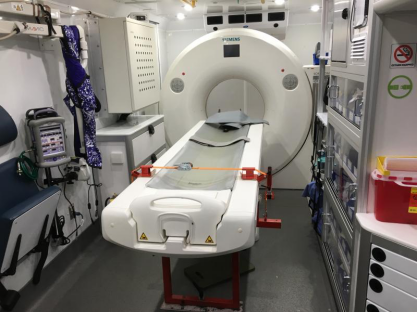

CNC machines also have the capability of creating parts like X-ray machines which have more complex equipment pieces.

Since CNC machining is compatible with a wide variety of materials, it makes it easier and perfect for these kinds of production processes.

4. Electronic medical equipment

CNC machines also have the capability of creating parts like X-ray machines which have more complex equipment pieces.

With these Equipements, a wider variety of CNC machines can be used since these Equipements may not need to be biosafe.

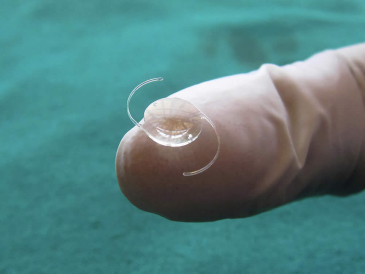

5. Intraocular lenses

An intraocular lens is a lens implanted in the eye as part of treatment for myopia. The process of CNC machining these lenses is delicate and precise. It requires expert skills and knowledge.

First, they design and create the lenses using Computer-aided Design software (CAD). They then send the lenses to a CNC milling machine where they are cut and shaped to the desired specifications.

The CNC milling machines have caused positive impacts on the medical sector. They have increased the productivity of medical equipment and parts due to their ability in mass production. This ensures that the supply of this equipment is good and consistent.

Also, in cases of medical emergencies, CNC machining is reliable. Because their machines are designed to work quickly and accurately, which increases the speed of production of medical parts.

They are also used to create one-off parts for testing and evaluation. Their creation is more accurate and repeatable since they allow more precise control over the machining process. This helps reduce the cost of production by reducing the use of manual labor.

They also produce medical Equipements with little or no waste. They are so precise in their products hence reducing the need for secondary machine operations. This helps save time and money.

Some medical equipment is used repeatedly which means they must be durable. CNC machining ensures the production of strong and durable medical equipment. They also produce high-quality devices that ensure stability and a high level of function.

In conclusion, we have confirmed that most medical equipment requires precise production as they are so sensitive due to their functions. This means they need to be manufactured under high-precision technology which is done by CNC machines.

Also, most of the equipment demand flawlessness and ease of sterilization. This means their milling process must be accurate in terms of shaping and making them frictionless. CNC milling plays a big part in that sector.