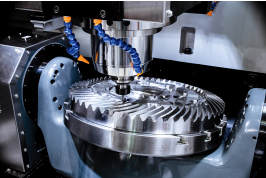

Numerous companies look for CNC milling machines for their operations so they can take through exact plans and make exact pieces with a computer program. A few businesses, from the therapeutic field to transportation, depending on machining parts. Much appreciated to the headway of both computers and machines, the CNC milling machine permits for more complicated customized plans than other generation strategies can accomplish.

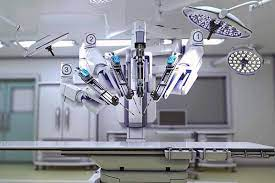

Medical Industry

The medical field depends on customized, quality items to fit patients' different needs. In any case, this industry moreover employs numerous expendable gadgets to secure patients from catching contaminations or illnesses whereas getting proper medical care. Therapeutic businesses require tall volumes of exact parts to fulfill their patient's needs and keep their offices supplied with fundamentals.

Once in a while, companies may ask models sometime recently starting full generation, particularly when testing modern thoughts. Models are basic within the medical field, as experts got to guarantee the items work well before using them on patients. The different sorts of CNC machines adjust well to the wants of the medical field. Due to the assortment of materials and gadgets accessible, medical specialists can have a wide extend of parts made through CNC machining, counting:

Orthotic devices

Electrical parts

Electronic enclosures for monitoring devices

Research equipment

Benefits of CNC machines within the medical field include the capacity to make customized parts quickly. Those in this industry, require the fabricating of these parts in FDA-approved situations. When making personal plans, the CNC program permits engineers to see all viewpoints of the piece in three measurements before machining it. This process ensures each component has the precise measurements it must work accurately. Parts that will fit together must have the littlest conceivable edge of mistake, as issues can lead to machine glitches and therapeutic misdiagnoses.

Aviation Industry

Devices within the aviation industry experience shifted conditions, counting high speeds, quick discuss streams, and extraordinarily high air pressure. To dodge flying machine harm, engineers must construct each component with the foremost exact devices and parts. Indeed, a little botch might capture an air current, creating drag or expanding wear on the parts.

Aerospace CNC milling machines must meet fantastically exact necessities, such as resistances as tight as 0.00004 inches. Mechanics must follow such resistances with extra-durable industry-standard materials such as titanium, aluminum, nickel, and a few plastics. Correct materials depend on the parts being made and the desired properties of that CNC component.

Transportation Industry

Many flying industry components, such as motors, may moreover be utilized within the transportation industry. Item investigation and testing are fair as crucial to the transportation division. After all, it is to the discussion and space industry, because it influences people's security and capacity to travel. Vehicle architects have to test physical part models so they know how to alter their unique plans and models for superior comes about.

CNC machining permits engineers to form models, test their common sense, and in the long run make a plan with the precise determinations they need. While the discussion and space industry requires creates built for speeds speedier than sound, the transportation division requires a life span.

Oil and Gas Industry

The petrochemical industry employments expensive machines for refineries and boring rigs. This line of work depends on well-machined, precise-fitting parts. Without an idealized fit, issues such as valve spills, cylinder disappointments, or barrel glitches may emerge. To attain effective offices, petrochemical companies need components made from the foremost exact CNC milling machines.

Drilling rigs are another put where parts must have high resistance. Not at all like other offices, penetrating rigs work in isolated areas. In case a CNC component falls flat to work because it ought to, getting a substitution or repair may take days away from generation. Parts created for utilization on rigs must work well the primary time and proceed operations well into the long run, indeed within the nearness of salt splash from the ocean, clean from the forsake or snow from the northern plains.

Military and Defense Industry

Similar to the oil and gas industry, the defense division requires solid parts that withstand indeed the harshest situations. The government sets strict directions for military movement. Fair as medical supplies must have their generation fulfill rules made by the FDA, military items have to be government regulations. The military as an entire envelops a multitude of divisions. Items and parts made for defense could seem comparable to those from other businesses, such as the flying, electronics, marine, transportation, and restorative businesses. In any case, these other businesses don't have as much got to keep up with the most recent innovation whereas having to get to solid parts within the most inaccessible areas.

Marine Industry

The marine industry owes its victory to the different CNC-milling machined components and their employment. Numerous watercraft components require unordinary materials or shapes, and machining is the culmination strategy for the assembly of those needs with negligible effort. Unlike other segments, the marine industry requires a high degree of water resistance from its items since most components will have either coordinated water presentation or presentation to the mugginess around seas, lakes, and streams, which can wear out parts.

Most hardware doesn't work well in damp or damp situations. Marine items, be that as it may depend on water-resistant electrical components. Gadgets on board ships require extraordinary contemplations, such as lodgings to square water from interferometer with electrical forms. Moreover, parts utilized in or close to the sea must be corrosion-resistant, as salt water can effortlessly dissolve the off-base materials. Marine applications moreover require a high degree of movability and strength.

Electronics

There could be a drift of miniaturization inside the buyer gadgets industry. Components are ceaselessly getting to be smaller, yet more capable than some time recently. The parts got to be compact and lightweight as well. small scale CNC machining is culminated for taking care of the specialized materials that are required for this. Cases of items made for gadgets through CNC machines are:

Electrical Insulation

Housings for amplifiers

Heat sinks

Shielding against radio frequency interference